3 min read

Energising your workspaces

There is a growing demand for office space to be comfortable and energising. Post-pandemic, with working from home having become the norm, the focus is now on wellbeing as well as productivity.

Read more

2 minutes

Sponge Christmas Campaign 2023

Our Christmas campaign was a brilliant collaborative effort between our Design Studio and Client Services Team.

Read more

3 mins

Time to get social

We are thrilled to announce the launch of our Social Media Services for you. It’s time for us to unlock your brands true potential through the power of Social Media.

Read more

Changemakers

At Sponge, we are thrilled and excited to sponsor the Changemaker Award as part of the Norfolk Women’s Marketing Awards 2023. To celebrate other standout changemakers in our region, we thought we’d spend a little time acquainting ourselves with a few mould-breakers and action-takers.

Read more

International Women’s Day

On International Women’s Day, we’re excited to share some of our formative influences and inspirations. We want to shine a light on a handful of amazing female talents within the creative sphere, each of whom has motivated us on our creative journeys.

Read more

A look back…

…And just like that, it’s the end of 2022! We launched our new brand identity, signed new clients, and progressed some amazing projects with our existing family of fantastic clients too.

Read more

3 min read

Trends for 2023

With 2022 coming to a close, reflecting on the trends of the last year are crucial to predict the funkiest, and upcoming trends for 2023.

Read more

5

The psychology of brands and the role of emotion

There are lots of reasons why we choose one brand over another. In this blog we take a look at how marketers try to influence our decision making process.

Read more

5 mins

Pandemic fuels changes in residential design

The top priorities for those buying residential properties have changed following the Covid-19 pandemic. A survey of developers around the world says home office space, storage for bikes, and larger outdoor areas would feature more often in designs for living space.

Read more

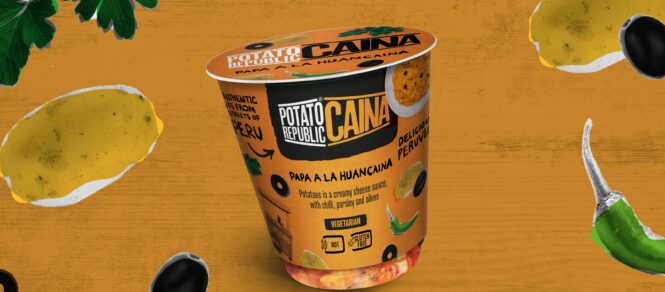

Rebranding our design agency.

The agency has been restructured and has adapted to the current industry landscape. We have simplified our approach to projects and are focusing on producing standout, high quality creative that exceeds expectations. As an agency we’ve matured over the pandemic, coming out stronger and more streamlined. Now our brand needs to do the same…

Read more

4 min read

How buyer personas can drive engagement and sales

Personalised marketing utilising insightful customer research will give your creative marketing campaigns granularity and focus.

Read more

5 min read

One size doesn’t fit all

With advertising channels ever evolving, changing size, shape and interaction methods – it’s no longer a case of one size fits all when thinking about logo design.

Read more

4 min read

How UX can boost your business’s growth plans.

The way in which many people approach solving any problem is generally biased – that’s because we’re more aware of our own needs and problems than we are of other people’s.

Read more

Design trends for 2024

It’s that time of year again…

The world of graphic design is constantly evolving, with new and exciting trends emerging all the time.

Here, we’ve explored eight of the hottest upcoming design trends we expect to see develop through the coming year.

Read more